A more environmentally friendly future depends on careful material selection, a crucial aspect as the construction industry shifts towards sustainability. Partel’s dedication to innovative building solutions is precisely tailored to meet the demands of steel and timber frame construction, empowering builders to embrace sustainability wholeheartedly. In this article, we explore how these solutions can transform construction techniques, promoting durability, energy efficiency, and environmental responsibility.

The rising demand for off-site construction stems from its rapid, efficient, cost-effective, and eco-friendly advantages, catalysing a real-time revolution in the construction industry. However, despite its pivotal role, the sector faces challenges, particularly in meeting the escalating demand for residential services. Market-driven solutions have fallen short, leaving many unable to afford housing. Residential construction grapples with low productivity, inconsistent quality, delayed output, and narrow profit margins, exacerbated by the cyclical sales-driven trader model.

Off-site manufacturing emerges as a solution to these challenges while also enhancing industry capacity and investment. Its unique properties can complement existing capacities, enabling alternative delivery models and expanding housebuilding options. However, it’s crucial to recognise that off-site manufacturing isn’t a panacea for sectoral problems. Nevertheless, once fully integrated, it holds immense potential to significantly improve our ability to meet housing demand.

So what are the current options in offsite construction?

Strength in Sustainability: Timber Frame Construction

Timber is a highly desirable and cost-effective building material that is carbon-neutral, resilient, renewable, and adaptable. The embodied carbon footprint of a material can be greatly decreased by substituting wood for energy- and carbon-intensive materials like steel or concrete.

The “fabric first” philosophy promoted by timber frame construction improves a building’s thermal envelope by providing better insulation. This method requires less maintenance because it relies less on mechanical heating and cooling systems. As a result, it supports Future Homes Standards and zero carbon home goals by helping to meet energy efficiency targets and reduce carbon emissions.

Harnessing the benefits of wood as a renewable resource lies at the core of timber frame construction. Our range of products complements this ethos, offering solutions that enhance waste reduction, thermal performance, and energy efficiency in wood-framed buildings. Our selection equips builders with the tools to construct enduring, eco-friendly timber frame structures.

Recent case Study:

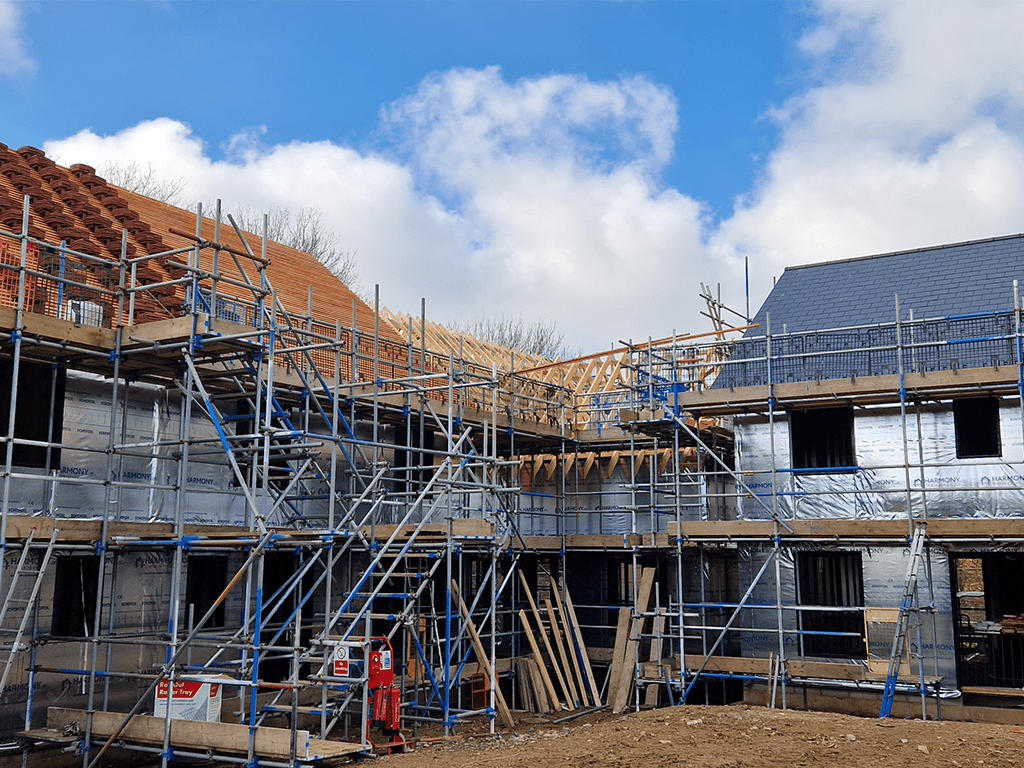

Reviving Tradition with Innovation: From Historical Farmland to Sustainable Timber Frame Homes in Kent

Products listed:

ECHOFOIL EXO Reflective Breathable Membrane

ACRABOND LIQUID

ECHOSEAL Foil Tape

Steeling Sustainability: Steel Frame Construction

To begin with, steel frame construction transforms building methods by offering a flexible and lightweight substitute for conventional building materials. Because of steel’s highly tensile strength, architects and engineers can easily create complex and innovative structures with greater structural integrity and design flexibility. Steel components can also be prefabricated off-site, which cuts labour costs and speeds up construction. Buildings that are manufactured off-site have higher precision and quality control, making them more robust and long-lasting.

Steel frame building solutions also show a dedication to environmental responsibility by reducing environmental impact over the course of the building lifecycle. Steel is an extremely recyclable material; post-consumer and industrial sources account for a significant percentage of the recycled steel used in construction. As a result, there is less of a need for virgin materials and less garbage dumped in landfills. Additionally, by lowering the need for frequent replacements and renovations, the strength and longevity of steel-framed buildings support sustainable development. The large volumes of steel produced in Europe – 160 million tonnes – are made with significant amounts of scrap steel. 56% of EU steel is made from scrap, with around 100 million tonnes of scrap steel recycled per annum1.

By integrating products specifically tailored for steel frames, such as high-performance insulation materials and advanced weatherproofing systems, builders can erect environmentally responsible and high-performing sustainable steel structures that meet stringent energy efficiency standards.

Case Study:

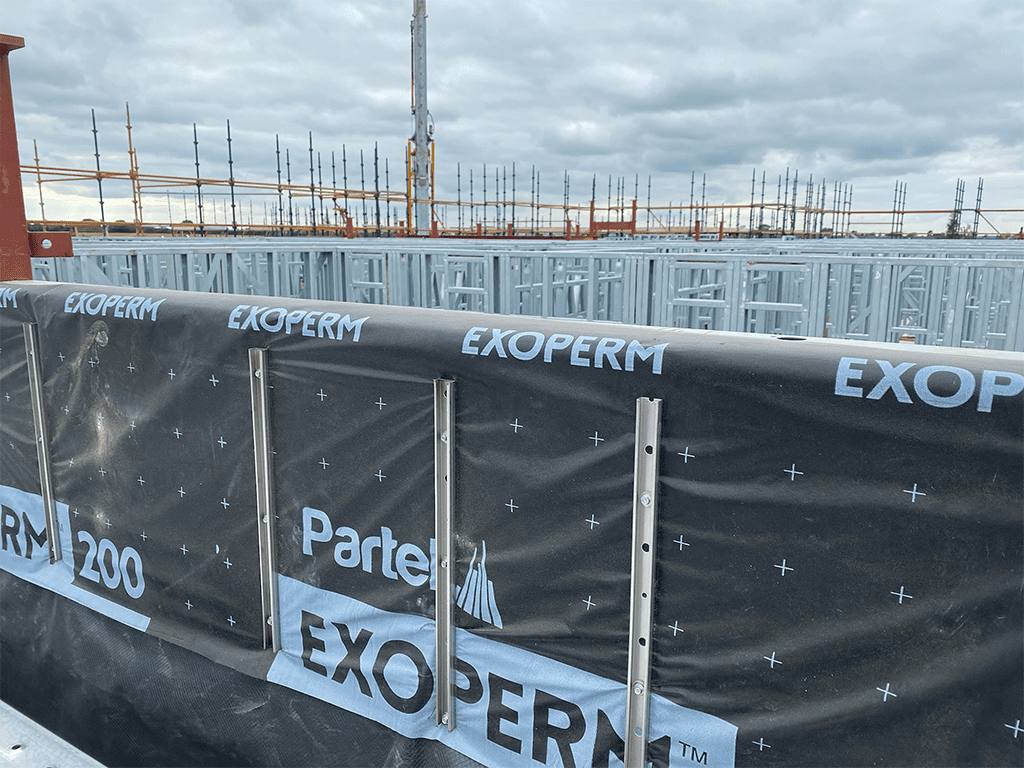

Whitethorn Village, LGS Frame Apartments

Products listed:

EXOPERM MONO DURO Fire Rated Monolithic Breather Membrane

ECHOSEAL ALU FR

VERBOND Hybrid Adhesive

IZOPERM PLUS Vapour Control Membrane

VARA SEAL Tape

Integrated Approaches to Eco-Friendly Building

Our integrated approach to sustainable construction sets a benchmark for excellence in the industry, reducing carbon emissions, conserving resources, and enhancing building performance.

Adopting off-site manufacturing techniques is beneficial for both timber frame and steel frame construction. Simplifying manufacturing procedures in controlled factory settings maximises material utilisation, minimises waste, and has a minimal negative impact on the environment. Precise component fabrication guarantees structural integrity and shortens the time spent building on site. Off-site construction happens concurrently with site foundation work, speeding up the entire build process and accelerating completion dates and schedules. Because most building components are pre-assembled in the factory, faster installation leads to shorter on-site times. Building professionals can minimise environmental impact, cut costs, and shorten project schedules by using off-site manufacturing. This will help progress the construction industry towards a more sustainable future.

Promoting Innovation for a Greener Future

We endeavour to advocate sustainability through a culture of continuous innovation and environmental stewardship, through our products. In partnership with engineers, architects, and builders, we work to advance sustainable building practices by promoting innovation in building methods and materials. The concepts of resilience, sustainability, and creativity are deeply embedded in our steel and wood frame construction solutions. By choosing our products, builders can jumpstart their efforts towards a more environmentally friendly future, with every building project contributing to a more sustainable built environment.

1. https://www.eurofer.eu/issues/environment/circular-economy